I. Introduction

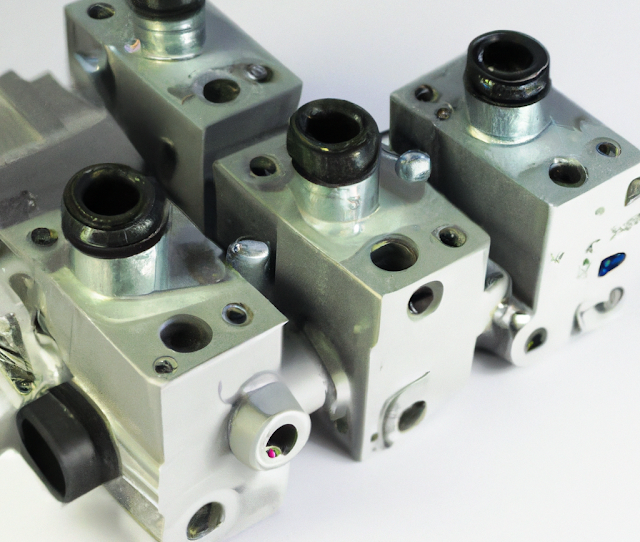

Fluid control components are essential elements in various industries, including manufacturing, oil and gas, and chemical processing. These components are responsible for regulating and controlling the flow, pressure, and temperature of fluids in various systems. One of the most critical components in fluid control is the solenoid valve.

A. Explanation of Fluid Control Components

Fluid control components are devices used to control the flow, pressure, and temperature of fluids in various systems. These components can be found in almost every industry, from water treatment plants to oil refineries. The primary function of fluid control components is to ensure that fluids flow smoothly and consistently, with the correct pressure and temperature.

B. Importance of Solenoid Valves

Solenoid valves are one of the most important fluid control components, providing a quick and reliable method of controlling the flow of fluids in various systems. These valves operate using an electromagnetic field, which opens or closes the valve depending on the current flowing through the coil. Solenoid valves are versatile and can be used in a wide range of applications, from controlling the flow of water in HVAC systems to regulating the flow of fuel in engines.

C. Overview of Various Fluids

Fluids can be categorized into different types based on their physical properties, including viscosity, density, and chemical composition. Some common types of fluids include liquids, gases, and viscous or corrosive fluids. The characteristics of these fluids can affect the performance and durability of fluid control components, making it essential to choose the right components for specific applications.

In the following sections, we will explore the basics of solenoid valves and the features and benefits of using these valves for different types of fluids. We will also provide guidance on selecting and installing solenoid valves and discuss emerging trends and developments in solenoid valve technology.

II. Solenoid Valve Basics

A. Definition and Function of Solenoid Valves

Solenoid valves are electromechanical devices used to control the flow of various fluids, including liquids, gases, and viscous materials. The valve is operated by an electric current that energizes a solenoid, which then moves a plunger, opening or closing the valve. Solenoid valves are commonly used in various industries, including manufacturing, automotive, medical, and food processing.

B. Types of Solenoid Valves

Direct Acting Solenoid Valves

Direct acting solenoid valves have a simple design and are typically used for low-pressure applications. In these valves, the plunger is directly connected to the seal, which opens and closes the valve orifice as the plunger moves. Direct acting solenoid valves are commonly used in small-scale applications such as medical devices and laboratory equipment.

Pilot Operated Solenoid Valves

Pilot operated solenoid valves have a more complex design and are typically used in high-pressure applications. These valves have two chambers, with the pilot chamber controlling the flow of fluid to the main chamber. The solenoid activates a pilot valve, which in turn opens or closes the main valve. Pilot operated solenoid valves are commonly used in industrial applications such as water treatment and chemical processing.

C. Components of Solenoid Valves

Coil

The coil is the electromagnetic component of the solenoid valve. When an electric current is passed through the coil, it generates a magnetic field, which moves the plunger.

Plunger

The plunger is the component of the solenoid valve that moves in response to the magnetic field generated by the coil. The plunger is typically made of ferromagnetic material and is connected to the seal.

Spring

The spring is a component of the solenoid valve that provides a restoring force to the plunger when the coil is no longer energized.

Seal

The seal is the component of the solenoid valve that opens and closes the valve orifice. The seal is typically made of a material that is compatible with the fluid being controlled by the valve.

D. Operating Principles of Solenoid Valves

Solenoid valves operate on the principle of electromagnetism. When an electric current is passed through the coil, it generates a magnetic field, which attracts the plunger, causing it to move. The movement of the plunger opens or closes the valve orifice, controlling the flow of fluid through the valve. When the electric current is no longer passed through the coil, the spring returns the plunger to its original position, closing or opening the valve orifice as appropriate.

III. Solenoid Valves for Various Fluids

A. Definition and Explanation of Various Fluids

Various fluids refer to any type of fluid, liquid, or gas that requires regulation and control in industrial and commercial settings. These fluids can range from simple water or air to more complex fluids such as chemicals, fuels, or acids.

B. Types of Various Fluids

Liquid-based Fluids

Liquid-based fluids are commonly used in industrial and commercial applications, such as water treatment plants, chemical processing, and food and beverage manufacturing. Some examples of liquid-based fluids include water, oil, hydraulic fluid, and chemicals.

Gas-based Fluids

Gas-based fluids are also widely used in industrial and commercial applications, such as HVAC systems, gas pipelines, and fuel processing. Some examples of gas-based fluids include natural gas, propane, and compressed air.

Viscous and Corrosive Fluids

Viscous and corrosive fluids can be particularly challenging to control and regulate, requiring specialized solenoid valves that can withstand the harsh conditions. Some examples of viscous and corrosive fluids include molten metal, acids, and adhesives.

C. Features and Benefits of Solenoid Valves for Various Fluids

Material Selection

The material selection for solenoid valves for various fluids is critical to ensure the valves can withstand the chemical properties and temperature of the fluid. Solenoid valves can be made from a range of materials, including stainless steel, brass, and plastic.

Seal Selection

The seal selection is also critical to ensure the solenoid valves can prevent fluid leaks and operate efficiently. Different seal materials are available, including NBR, Viton, and EPDM, depending on the fluid type and operating conditions.

Pressure and Temperature Rating

Solenoid valves for various fluids are rated for different pressure and temperature ranges to ensure they can operate safely and efficiently in different applications.

Flow Rate

Solenoid valves for various fluids are available in various sizes and configurations to accommodate different flow rates, ensuring that they can meet the specific needs of the application.

D. Examples of Various Fluid Applications for Solenoid Valves

Industrial and Manufacturing Applications

Solenoid valves are widely used in industrial and manufacturing applications, such as chemical processing, water treatment, and oil and gas refineries, to control and regulate the flow of various fluids.

HVAC Systems

Solenoid valves are used in HVAC systems to control the flow of refrigerant, ensuring that the system operates efficiently and effectively.

Automotive and Transportation

Solenoid valves are used in automotive and transportation applications, such as fuel injection systems and brake systems, to regulate and control the flow of various fluids, ensuring optimal performance and safety.

IV. Selection and Installation of Solenoid Valves for Various Fluids

A. Considerations for Selecting Solenoid Valves for Various Fluids

When selecting solenoid valves for various fluids, several considerations must be taken into account to ensure that the valves are compatible with the fluids and operating conditions.

Fluid Compatibility

The first consideration is fluid compatibility. Different fluids have different properties and can react with certain materials or seals in the valves. Therefore, it is essential to select solenoid valves that are compatible with the specific fluids being used.

Operating Conditions

The operating conditions of the system must also be taken into account when selecting solenoid valves. These conditions include factors such as pressure, temperature, and viscosity. It is crucial to choose valves that are capable of operating effectively under the specific conditions of the system.

Electrical Requirements

Another consideration is the electrical requirements of the system. Solenoid valves require a specific voltage and current to operate correctly. It is important to ensure that the selected valves are compatible with the electrical system and can function reliably.

Flow Rate Requirements

Lastly, the flow rate requirements of the system should also be considered when selecting solenoid valves. The valves must be capable of providing the necessary flow rate to meet the requirements of the system.

B. Installation Best Practices

Proper installation of solenoid valves is essential for their effective operation and longevity. The following best practices should be observed during installation:

Proper Orientation

Solenoid valves should be installed in the proper orientation to ensure that the fluid flows through them in the correct direction. Incorrect orientation can result in reduced performance and premature failure of the valve.

Electrical Wiring

Electrical wiring should be performed by a qualified electrician to ensure that it is done correctly and safely. Proper wiring ensures that the solenoid valve operates reliably and efficiently.

Maintenance and Troubleshooting

Regular maintenance is essential to ensure that solenoid valves operate effectively and have a long lifespan. Maintenance should include inspection, cleaning, and replacement of any worn or damaged components. Troubleshooting should also be performed promptly to identify and address any issues that may arise.

Proper selection and installation of solenoid valves for various fluids are crucial for their effective operation and longevity. Observing the above considerations and best practices ensures that the valves provide reliable performance and reduce the risk of system failure.

V. Emerging Trends and Developments in Solenoid Valves for Various Fluids

The field of fluid control components is constantly evolving, with new advancements and technologies emerging all the time. As such, it is important to stay up to date with the latest trends and developments in solenoid valves for various fluids.

A. Advancements in Materials and Manufacturing

One major trend in solenoid valves for various fluids is the advancement of materials and manufacturing techniques. New materials are being developed that offer better resistance to corrosion, wear and tear, and extreme temperatures. These materials include alloys, ceramics, and composites.

Manufacturing techniques are also improving, allowing for more precise and efficient production of solenoid valves. For example, 3D printing can be used to create complex geometries and custom designs with greater speed and accuracy.

B. Increased Demand for Customized Solutions

Another trend in solenoid valves for various fluids is the increased demand for customized solutions. With the wide variety of fluids and applications out there, it is often necessary to design and manufacture solenoid valves that meet specific requirements.

Customized solutions can be achieved using modular designs, which allow for easy customization of components and features. Advances in software and simulation tools also make it easier to design and test customized solutions.

C. Impact of Automation and Industry 4.0

Finally, the trend towards automation and Industry 4.0 is having a significant impact on the development of solenoid valves for various fluids. As more and more systems become automated, the demand for solenoid valves that can be integrated into these systems is increasing.

To meet this demand, solenoid valves are being designed with advanced features such as remote monitoring, predictive maintenance, and wireless connectivity. These features allow for greater control and optimization of fluid control systems, leading to increased efficiency and productivity.

Overall, solenoid valves for various fluids will continue to evolve and improve as new technologies and trends emerge. By staying up to date with these developments, businesses can ensure that they are using the latest and most effective solutions for their fluid control needs.

VI. Conclusion

A. Summary of Key Points

Fluid control components, including solenoid valves, play a critical role in various industries that require precise control of fluids. Solenoid valves are versatile components that can be used to control different types of fluids, including liquids, gases, and even viscous or corrosive fluids. Solenoid valves work by using electromagnetic principles to control the flow of fluids, making them highly reliable and efficient.

Selecting the right solenoid valves for different fluid types requires careful consideration of factors such as fluid compatibility, operating conditions, and flow rate requirements. It is important to work with a reputable supplier of fluid control components that can provide technical expertise, support, and quality products.

B. Importance of Selecting the Right Solenoid Valves for Various Fluids

The selection of the right solenoid valves for various fluids is critical for ensuring optimal performance and efficiency in fluid control systems. Choosing the wrong solenoid valve can lead to system failures, safety hazards, and increased costs due to downtime, repairs, and replacements.

Working with a reputable supplier of solenoid valves that understands the unique characteristics of different fluids can help ensure that the right products are selected for each application. This can help minimize the risk of system failures, reduce costs, and improve overall system performance.

C. Outlook and Recommendations for Staying Ahead of Industry Trends

As technology and automation continue to evolve, the fluid control components industry is also changing. Manufacturers are increasingly focusing on developing customized solutions that can meet specific customer needs. This trend is likely to continue, as businesses seek to optimize their operations and improve their bottom line.

To stay ahead of industry trends, it is important to work with a supplier of fluid control components that is committed to staying abreast of new developments and innovations. This can help ensure that businesses have access to the latest products and solutions that can help them achieve their goals.

In conclusion, solenoid valves are critical components in fluid control systems. Selecting the right solenoid valves for various fluids is essential for achieving optimal performance and efficiency. By working with a reputable supplier of fluid control components and staying ahead of industry trends, businesses can stay competitive and achieve success in today's rapidly evolving market.

0 Komentar