I. Introduction

A. Explanation of Fluid Control Components

Fluid control components are essential devices that regulate the flow, pressure, and direction of fluids in various industrial applications. These components are used in a wide range of industries such as chemical processing, pharmaceuticals, food and beverage, water treatment, and many more. Fluid control components are essential for maintaining the stability and consistency of industrial processes, as well as ensuring the safety of workers and equipment.

B. Importance of Solenoid Valves

Solenoid valves are an important type of fluid control component that use an electromagnetic coil to control the flow of fluids. Solenoid valves are commonly used in a variety of applications due to their ability to provide precise control, high reliability, and fast response times. They are particularly useful in situations where automatic control of fluid flow is required, such as in automated manufacturing processes, HVAC systems, and water treatment systems.

C. Overview of Dedicated Fluids

Dedicated fluids are specialized fluids that are designed to perform specific functions in various industrial applications. These fluids are often used in critical processes that require high levels of precision, purity, and safety. Examples of dedicated fluids include medical and pharmaceutical fluids, food and beverage processing fluids, and industrial chemicals. Because these fluids have unique characteristics and properties, they require specialized fluid control components, such as solenoid valves, that are designed specifically for their use.

A. Definition and function of solenoid valves

Solenoid valves are electromechanical devices that are used to control the flow of fluids, including gases and liquids. They operate by using an electric current to create a magnetic field, which then moves a plunger or other component to either open or close a valve. This allows for precise control over the flow of fluids in a variety of applications.

B. Types of solenoid valves

There are two main types of solenoid valves: direct acting and pilot operated.

Direct acting solenoid valves

Direct acting solenoid valves are simple in design and operate by using a plunger that is directly connected to the valve. When an electric current is applied, the plunger moves and either opens or closes the valve. These types of valves are often used in low-pressure applications and where precise control over the flow of fluid is required.

Pilot operated solenoid valves

Pilot operated solenoid valves are more complex and are often used in higher-pressure applications. They consist of a small pilot valve that is connected to a larger valve. When an electric current is applied, the pilot valve opens, allowing fluid to flow into the larger valve, which then opens or closes. This type of valve is often used in industrial applications where large volumes of fluid need to be controlled.

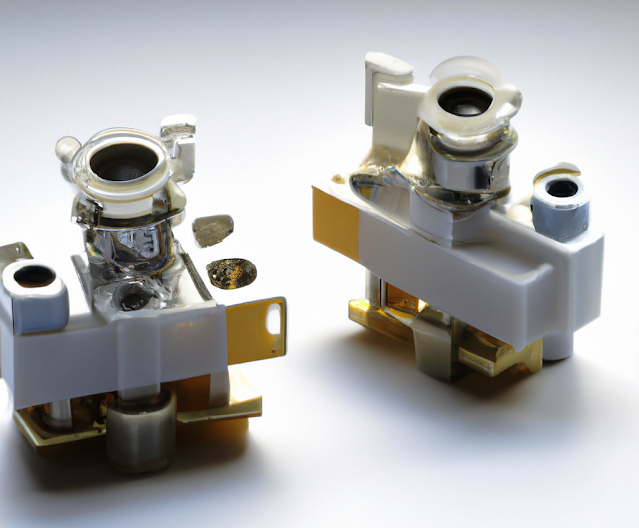

C. Components of solenoid valves

Solenoid valves consist of several key components that work together to control the flow of fluid.

Coil

The coil is the electrical component of the solenoid valve and is responsible for generating the magnetic field that moves the plunger.

Plunger

The plunger is a moveable component that is connected to the valve and moves in response to the magnetic field generated by the coil. When the plunger moves, it opens or closes the valve.

Spring

The spring is a component that provides resistance to the plunger and helps to return it to its original position when the magnetic field is removed.

Seal

The seal is a component that helps to prevent leakage of fluid around the valve. It is usually made from a flexible material such as rubber or silicone.

D. Operating principles of solenoid valves

Solenoid valves operate based on the principles of electromagnetism. When an electric current is applied to the coil, it generates a magnetic field that pulls the plunger towards it. This movement either opens or closes the valve, depending on the design of the solenoid valve. When the electric current is turned off, the spring returns the plunger to its original position and the valve returns to its previous state. The speed at which the valve operates can be controlled by adjusting the strength of the electric current applied to the coil.

III. Solenoid Valves for Dedicated Fluids

A. Definition and Explanation of Dedicated Fluids

Dedicated fluids are specific fluids that are designed for a particular application or process. These fluids are carefully formulated to meet the requirements of the specific application, and they often have unique chemical compositions and properties that make them suitable for the task at hand. Examples of dedicated fluids include medical-grade fluids, food-grade fluids, and industrial fluids that are used in chemical processing.

B. Types of Dedicated Fluids

Liquid-Based Dedicated Fluids

Liquid-based dedicated fluids are used in a wide range of applications, including medical, pharmaceutical, and food processing. These fluids may be water-based or oil-based, and they are designed to meet specific requirements such as viscosity, lubrication, and chemical resistance. Examples of liquid-based dedicated fluids include hydraulic fluids, coolant fluids, and lubricants.

Gas-Based Dedicated Fluids

Gas-based dedicated fluids are used in various industrial processes that require controlled environments or specific gas properties. These fluids are often used in the semiconductor, aerospace, and automotive industries. Examples of gas-based dedicated fluids include nitrogen, argon, and helium.

C. Features and Benefits of Solenoid Valves for Dedicated Fluids

Material Selection

Solenoid valves for dedicated fluids are made of materials that are compatible with the fluid being controlled. For example, solenoid valves for medical applications are often made of stainless steel or medical-grade plastics to avoid contamination of the fluid. The right material selection ensures that the solenoid valve does not corrode or erode when in contact with the fluid.

Seal Selection

The seal is an essential component of the solenoid valve, and it must be carefully selected to ensure that it is compatible with the fluid being controlled. Solenoid valves for dedicated fluids have seals that are resistant to chemical reactions and maintain their integrity over time.

Pressure and Temperature Rating

Solenoid valves for dedicated fluids have a pressure and temperature rating that is specific to the fluid being controlled. The pressure rating indicates the maximum pressure the valve can withstand without failure, while the temperature rating indicates the maximum temperature the valve can operate at without degrading.

Flow Rate

The flow rate of a solenoid valve is critical to the performance of the system it is controlling. Solenoid valves for dedicated fluids are designed to handle specific flow rates to ensure that the fluid is controlled accurately.

D. Examples of Dedicated Fluid Applications for Solenoid Valves

Medical and Pharmaceutical Applications

Solenoid valves are used in various medical and pharmaceutical applications, including drug delivery systems, surgical instruments, and medical gas supply systems. Solenoid valves for medical applications are often made of materials that are compatible with the fluid being controlled and have high-pressure ratings to ensure the safe delivery of medical fluids.

Food and Beverage Processing

Solenoid valves are used in the food and beverage industry to control the flow of liquids, gases, and steam. Solenoid valves for food-grade fluids are made of materials that are safe for human consumption and can withstand the harsh conditions of food processing environments.

Chemical Processing

Solenoid valves are used in various chemical processing applications, including water treatment, petrochemicals, and industrial gases. Solenoid valves for chemical processing are made of materials that can withstand the corrosive nature of chemicals and have high-temperature and pressure ratings to ensure safe and accurate control of the fluid.

IV. Selection and Installation of Solenoid Valves for Dedicated Fluids

A. Considerations for selecting solenoid valves for dedicated fluids

When selecting solenoid valves for dedicated fluids, there are several key considerations that must be considered. These considerations include:

- Fluid compatibility: One of the most important considerations when selecting a solenoid valve for dedicated fluids is the compatibility of the valve with the specific fluid being used. It is essential to choose a solenoid valve that is constructed from materials that are compatible with the fluid to avoid any negative effects on the valve or the fluid being used.

- Operating conditions: Solenoid valves for dedicated fluids must be able to operate effectively under specific conditions such as temperature, pressure, and flow rate. It is important to choose a valve that is designed to withstand the specific operating conditions of the application.

- Electrical requirements: Solenoid valves are powered by electrical current, and it is important to choose a valve that is compatible with the electrical requirements of the application. This includes considerations such as voltage, frequency, and wiring connections.

- Flow rate requirements: The flow rate of the fluid being controlled is also an important consideration when selecting a solenoid valve. It is important to choose a valve with an appropriate flow rate to ensure that the fluid is being controlled effectively.

B. Installation best practices

Proper installation is essential for ensuring that solenoid valves for dedicated fluids operate effectively and efficiently. Some best practices for installation include:

- Proper orientation: Solenoid valves for dedicated fluids must be installed in the correct orientation to ensure that they operate correctly. It is important to follow the manufacturer's instructions for proper installation orientation.

- Electrical wiring: Electrical wiring for solenoid valves for dedicated fluids must be installed correctly to ensure that the valve operates correctly. It is important to follow the manufacturer's instructions for electrical wiring and to ensure that the wiring is secure.

- Maintenance and troubleshooting: Regular maintenance is essential for ensuring that solenoid valves for dedicated fluids continue to operate effectively over time. This includes regular cleaning, inspection, and replacement of any worn or damaged components. Additionally, if the valve is not operating correctly, it is important to troubleshoot the issue to identify the cause and take corrective action.

By following these considerations and installation best practices, solenoid valves for dedicated fluids can be effectively selected and installed for optimal performance in any application.

V. Conclusion

A. Summary of key points

In summary, solenoid valves are important components in fluid control systems that play a critical role in regulating the flow of fluids in various industries. Solenoid valves for dedicated fluids offer specific features and benefits, including material and seal selection, pressure and temperature rating, and flow rate, which make them suitable for use in various applications, such as medical and pharmaceutical, food and beverage processing, and chemical processing. Selecting the right solenoid valves for dedicated fluids is crucial to ensure optimal system performance, efficiency, and reliability.

B. Importance of selecting the right solenoid valves for dedicated fluids

Selecting the right solenoid valves for dedicated fluids is essential to ensure optimal system performance, reliability, and safety. Factors such as fluid compatibility, operating conditions, electrical requirements, and flow rate requirements must be considered when selecting solenoid valves. Choosing the wrong type of solenoid valve can lead to system failure, downtime, and costly repairs. Therefore, it is important to work with a reputable supplier, such as PT Duta Swarna Dwipa, that has expertise in fluid control components to ensure that the right solenoid valves are selected and installed.

C. Future trends and developments in fluid control components

The fluid control components industry is continuously evolving, with new technologies and materials being developed to meet the changing needs of various industries. In the future, we can expect to see more advanced solenoid valves with improved features and functionalities, such as higher pressure and temperature ratings, better flow control, and increased durability. Additionally, the industry is likely to see an increased focus on sustainability and energy efficiency, with the development of solenoid valves that reduce energy consumption and minimize environmental impact. As the industry continues to evolve, it is important to stay up-to-date with the latest trends and developments to ensure that fluid control systems are optimized for efficiency and performance.

VI. Supplier of Solenoid Valves for Dedicated Fluids in Karawang and Bekasi Area

A. Introduction to PT Duta Swarna Dwipa

PT Duta Swarna Dwipa is a leading supplier of fluid control components, including solenoid valves for dedicated fluids in the Karawang and Bekasi area. The company has been in operation for several years and has established itself as a reliable and trusted supplier of high-quality fluid control components.

Company Overview

PT Duta Swarna Dwipa has a strong presence in the fluid control components industry, providing a wide range of products to various industries such as oil and gas, water treatment, pharmaceuticals, and many others. The company's primary focus is on providing quality products and exceptional customer service, making them one of the most reputable suppliers in the area.

Products and Services Offered

PT Duta Swarna Dwipa offers a comprehensive range of fluid control components, including solenoid valves, pressure gauges, regulators, and flow meters, among others. The company also offers installation, maintenance, and repair services, ensuring that their customers receive the best possible service.

B. Explanation of PT Duta Swarna Dwipa's Expertise in Fluid Control Components

PT Duta Swarna Dwipa has a team of experienced professionals who are experts in fluid control components. The team provides technical support and advice to customers, helping them choose the right products for their specific needs. The company also has strong relationships with leading manufacturers in the industry, ensuring that they always have access to the latest and most innovative products.

C. Solenoid Valves for Dedicated Fluids Offered by PT Duta Swarna Dwipa

Types of Solenoid Valves

PT Duta Swarna Dwipa offers a variety of solenoid valves for dedicated fluids, including direct acting and pilot operated solenoid valves. The company also offers a range of sizes and configurations to suit different applications.

Materials and Seal Selection

PT Duta Swarna Dwipa offers solenoid valves made from a range of materials, including brass, stainless steel, and plastic. The company also offers various seal materials, such as NBR, Viton, and EPDM, to suit different fluid types and operating conditions.

Pressure and Temperature Rating

The solenoid valves offered by PT Duta Swarna Dwipa have varying pressure and temperature ratings, making them suitable for different applications. The company also provides advice on choosing the right solenoid valves based on the operating conditions.

Flow Rate

PT Duta Swarna Dwipa offers solenoid valves with varying flow rates, ensuring that their customers can find a product that meets their specific needs.

D. Benefits of Working with PT Duta Swarna Dwipa for Solenoid Valves

High-Quality Products

PT Duta Swarna Dwipa only offers products from reputable manufacturers in the industry, ensuring that their customers receive high-quality and reliable products.

Technical Expertise and Support

The company has a team of experienced professionals who can provide technical support and advice to customers. This ensures that customers can choose the right products for their specific needs and receive the best possible service.

Competitive Pricing

PT Duta Swarna Dwipa offers competitive pricing on all their products, ensuring that their customers receive value for money.

E. Coverage Area of PT Duta Swarna Dwipa

Karawang

PT Duta Swarna Dwipa has a strong presence in the Karawang area and provides fluid control components to various industries in the region.

Bekasi

The company also provides fluid control components to the Bekasi area, ensuring that their customers in the region have access to high-quality products and services.

Other Areas in Indonesia

PT Duta Swarna Dwipa also serves other areas in Indonesia, providing their customers with quality products and exceptional service, regardless of their location in the country.

F. Conclusion and Recommendation to Work with PT Duta Swarna Dwipa for Solenoid Valves for Dedicated Fluids in Karawang and Bekasi Area

PT Duta Swarna Dwipa is a leading supplier of fluid control components, including solenoid valves for dedicated fluids in the Karawang and Bekasi area. The company's expertise in fluid control components, high-quality products, technical support, and competitive pricing make them the ideal partner for businesses looking for solenoid valves for dedicated fluids.

If you're in need of solenoid valves for dedicated fluids in the Karawang and Bekasi area, we highly recommend working with PT Duta Swarna Dwipa. The company's commitment to quality and customer service ensures that you receive the best possible products and support, helping you achieve optimal performance and efficiency in your operations.